Inventory management costs U.S. businesses $1.1 trillion annually in carrying costs alone. Traditional methods leave companies struggling with stockouts that cost retailers $1 trillion globally each year.

AI for inventory management changes this reality. We at Emplibot see companies reducing inventory costs by 20-30% while improving stock availability to 99%+ through smart automation and predictive analytics.

Contents

ToggleHow AI Transforms Inventory Performance

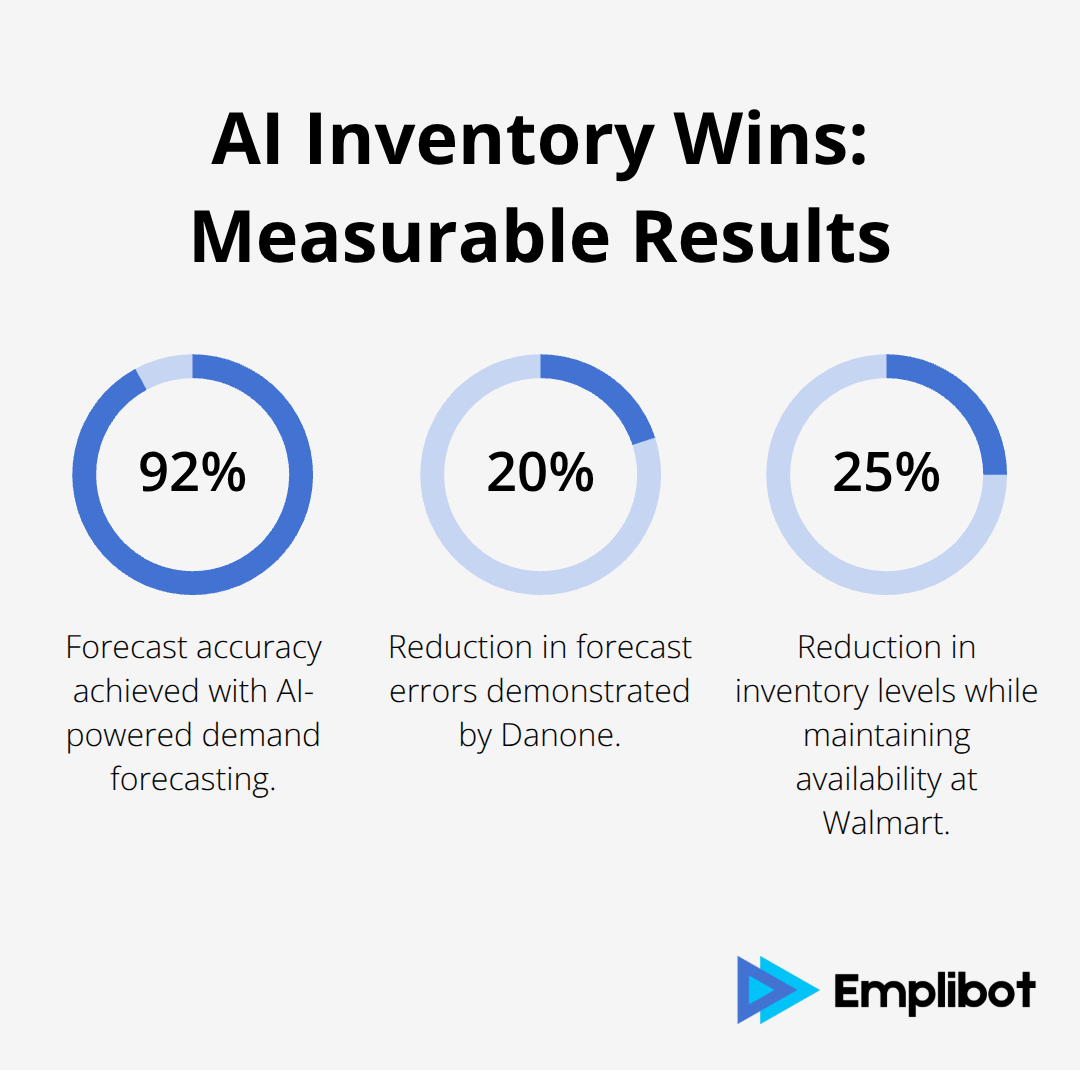

AI transforms inventory performance through three measurable improvements that directly impact your bottom line. Companies that use AI-powered demand forecasting see forecast accuracy improve to 92%, as Danone demonstrated with their 20% reduction in forecast errors. Walmart reduced inventory levels by 25% while it maintained stock availability, which proves that AI systems can simultaneously cut costs and improve service levels.

Stockout Prevention Through Predictive Analytics

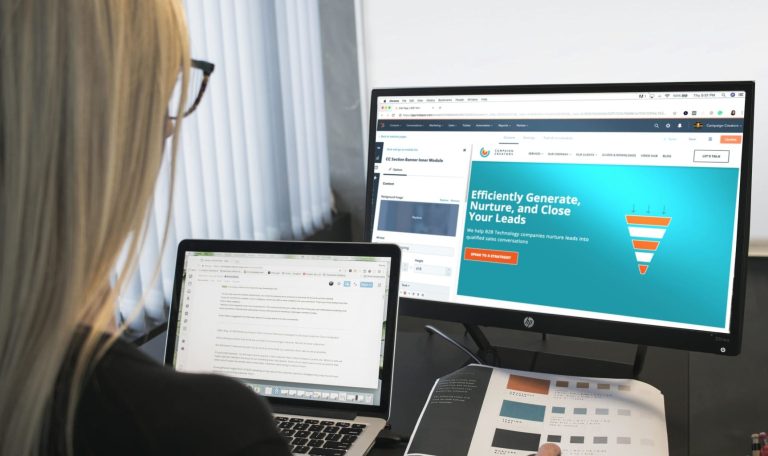

AI systems analyze historical sales data, seasonal patterns, and external factors like weather or economic indicators to predict demand spikes before they occur. Companies implementing AI inventory management solutions see a 25% reduction in inventory costs and a 15% increase in sales, which directly improves customer satisfaction. Machine learning algorithms process thousands of data points per second and identify patterns human analysts miss.

Real-time inventory tracking powered by AI provides alerts when stock levels approach critical thresholds, which allows proactive replenishment decisions. Companies like Shelf Engine generated $40 million in incremental profit within one year after they implemented AI-driven demand forecasting that prevented both stockouts and waste.

Cost Reduction Through Automated Procurement

AI automates reorder processes when it monitors stock levels continuously and triggers purchase orders when inventory reaches predetermined thresholds. Major retailers in North America and Europe will reduce inventory carrying costs by 30%. Automated systems eliminate human errors in order quantities and timing, while they optimize supplier selection based on delivery performance, pricing, and quality metrics.

AI-powered procurement systems analyze supplier data to negotiate better terms and identify alternative sources during supply disruptions. These systems create resilient supply chains that adapt to market changes without manual intervention (a capability that becomes essential during economic uncertainty).

Enhanced Accuracy Through Real-Time Data Analysis

AI systems process vast amounts of data quickly and accurately, which minimizes errors that plague traditional inventory management approaches. These systems continuously monitor operations to identify inefficiencies and provide real-time insights that enable proactive decision-making. Advanced algorithms analyze multiple variables simultaneously-from supplier performance metrics to customer behavior patterns-creating a comprehensive view of inventory needs.

The technology also automates routine tasks like sales order creation and inventory tracking, which frees staff to focus on strategic activities. This shift from reactive to proactive management represents a fundamental change in how businesses approach inventory management, setting the foundation for the specific AI technologies that make these improvements possible.

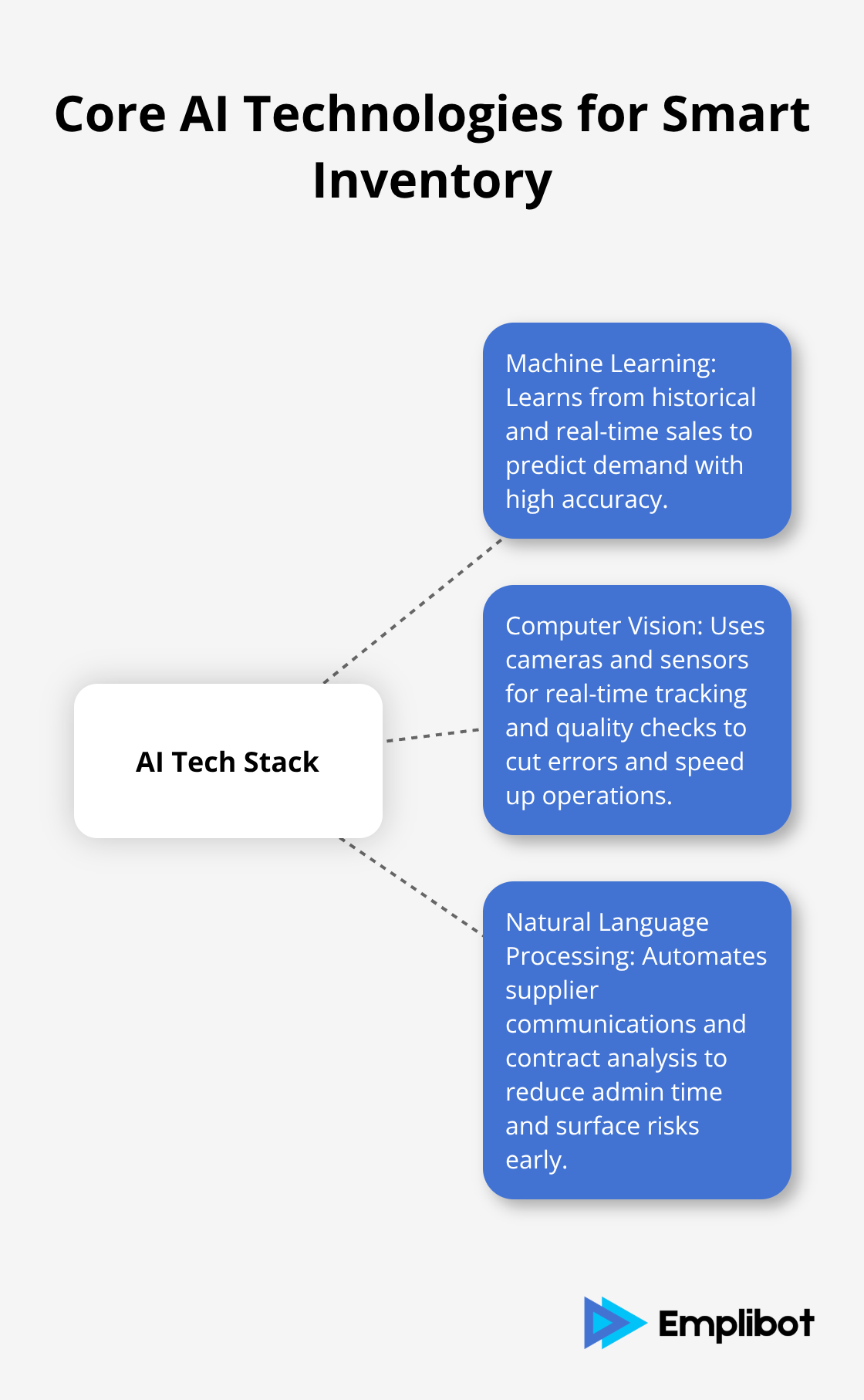

Which AI Technologies Drive Smart Inventory Management

Machine learning algorithms form the backbone of modern inventory systems through their ability to process massive datasets and identify demand patterns that human analysts cannot detect. Companies that use machine learning for demand prediction achieve improved forecast accuracy, while systems like those that Danone implemented reduce forecast errors by 20%. These algorithms analyze historical sales data, seasonal trends, market conditions, and external factors like weather patterns to generate precise demand forecasts. The technology continuously learns from new data, which means prediction accuracy improves over time without manual intervention.

Machine Learning Powers Predictive Analytics

Advanced machine learning models process thousands of variables simultaneously to predict inventory needs with remarkable precision. These systems identify subtle correlations between seemingly unrelated factors (such as social media trends and product demand) that traditional forecasting methods miss entirely. The algorithms adapt to changing market conditions automatically and adjust predictions based on real-time sales data, competitor actions, and economic indicators.

Computer Vision Transforms Warehouse Operations

Computer vision technology revolutionizes warehouse automation through real-time inventory tracking and automated quality inspections. These systems use cameras and sensors to scan items during receiving, stowing, and picking processes, which eliminates manual counting errors and reduces processing times by up to 40%. Major logistics companies deploy computer vision for dynamic slotting, which optimizes item placement based on demand patterns and reduces picking times significantly. The technology also enables autonomous mobile robots to navigate warehouses safely while they maintain 99.9% accuracy in order fulfillment.

Natural Language Processing Streamlines Supplier Relations

Natural Language Processing automates supplier communication through intelligent order processing and contract analysis. NLP systems process purchase orders, delivery confirmations, and supplier performance reports automatically, which reduces administrative overhead by 60% while it improves response times. These systems analyze supplier communications to identify potential disruptions early and suggest alternative sourcing options. Advanced NLP applications also generate automated responses to routine supplier inquiries and extract key information from contracts to optimize procurement decisions.

The combination of these three core technologies creates a foundation for intelligent inventory management that adapts to your business needs. The next step involves understanding how to implement these powerful AI business tools within your existing operations.

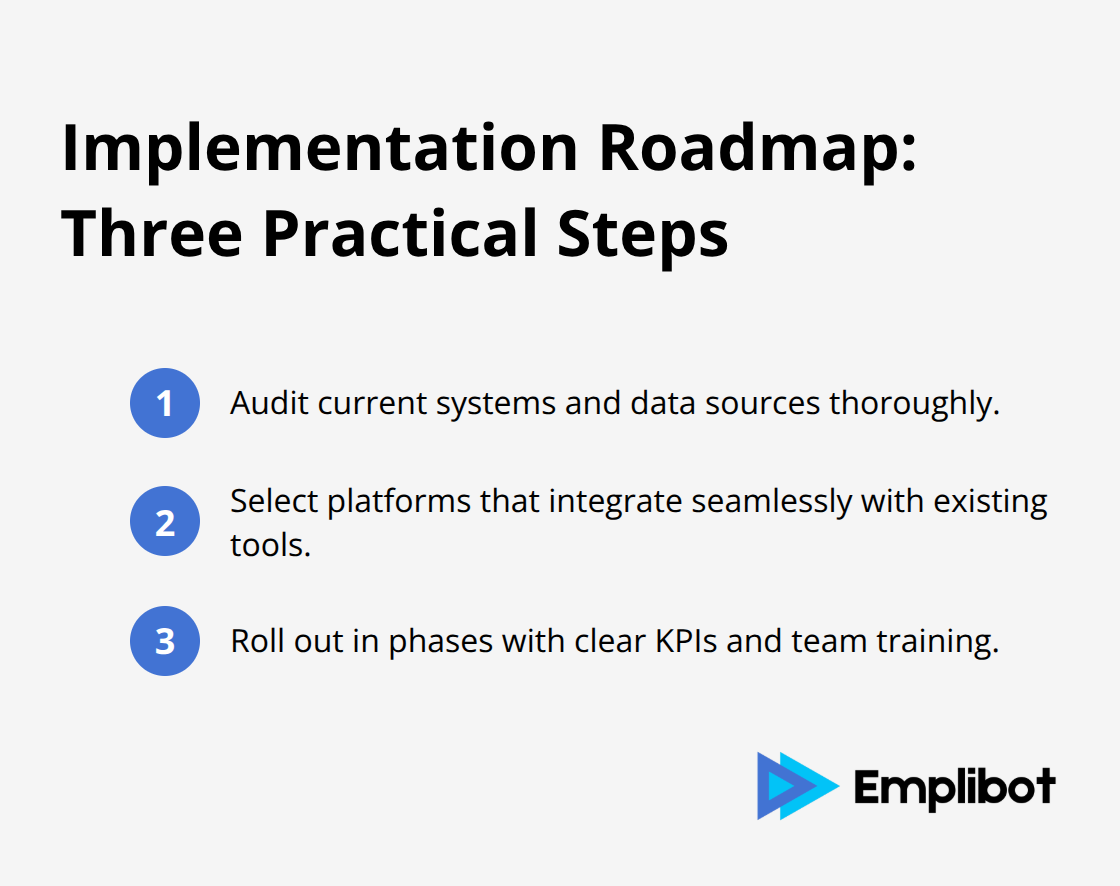

How Do You Actually Implement AI for Inventory Management

The path to successful AI inventory implementation starts with a comprehensive audit of your current systems and processes. Companies that skip this assessment phase face higher failure rates. Start with documentation of your existing inventory workflows, identification of data sources, and measurement of current performance metrics like forecast accuracy, stockout rates, and carrying costs.

Map out where your inventory data lives – whether in ERP systems, spreadsheets, or warehouse management platforms. This audit reveals data quality issues that you must address before AI implementation can succeed.

Start With Data Foundation and System Assessment

Your data quality determines AI success more than any other factor. Poor data quality costs organizations at least $12.9 million a year on average, which makes data preparation the most important step. Evaluate your historical sales data for completeness, accuracy, and consistency across all channels. Companies with clean, integrated data see better forecast accuracy after AI implementation. Focus on consolidation of data silos and establishment of real-time data feeds from all touchpoints – point-of-sale systems, e-commerce platforms, and supplier networks. Document current manual processes that consume significant staff time, as these become prime candidates for AI automation.

Choose Platforms Based on Integration Capabilities

Select AI platforms that integrate seamlessly with your existing infrastructure rather than require complete system overhauls. Cloud-based solutions offer faster deployment and continuous updates, while on-premise options provide greater control over sensitive data. Evaluate vendors based on their track record with companies similar to yours and their ability to scale with your growth. Pilot programs in controlled environments help identify potential issues before full deployment. Focus on platforms that offer pre-built connectors for your current systems and provide comprehensive training resources for your team.

Execute Phased Rollout With Measurable Milestones

Implement AI inventory systems in phases, start with your highest-volume or most predictable product categories. This approach allows your team to learn the system while it minimizes business disruption. Set specific KPIs for each phase – forecast accuracy improvements, cost reductions, and staff productivity gains. Clear success metrics help companies achieve their strategic, financial, and operational goals. Train key staff members to become AI system champions who can support broader adoption across your organization. Regular performance reviews during the first six months help fine-tune algorithms and optimize system parameters for your specific business needs (which ensures maximum ROI from your AI investment).

Final Thoughts

AI for inventory management delivers measurable results that transform business operations. Companies that implement these systems achieve 20-30% cost reductions while they maintain 99%+ stock availability. The technology eliminates the $1.1 trillion annual burden of inefficient inventory practices through predictive analytics, automated procurement, and real-time data processing.

Success depends on three factors: clean data integration, phased implementation, and staff training. Organizations that audit their current systems first and choose platforms with strong integration capabilities see faster ROI. Companies that start with pilot programs in controlled environments reduce risk while they build internal expertise.

The investment pays dividends immediately. Danone reduced forecast errors by 20%, while Walmart cut inventory levels by 25% without it compromised availability. Your next step involves assessment of current inventory processes and identification of data quality issues (focus on consolidation of information from all touchpoints before you select AI platforms). Just as Emplibot automates content marketing to drive traffic and sales, AI inventory systems automate complex decisions that previously required extensive manual analysis.